▌Yield Improvement & Energy Saving

Energy-Saving Engineering

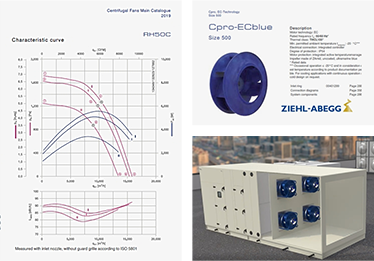

Energy conservation and carbon reduction have always been a topic of global concern. The factory's ice water system, compressed air system, and long-running windmills and water pumps account for a considerable proportion of the factory's energy consumption. In addition to purchasing high-efficiency operating equipment, the initial system planning and design, system operation methods during operation, and subsequent system maintenance will all affect the operating energy consumption of the entire system. Our team has considerable experience in plant construction and energy-saving improvement cases, and can help owners check whether there is room for energy-saving improvement in the operating system.

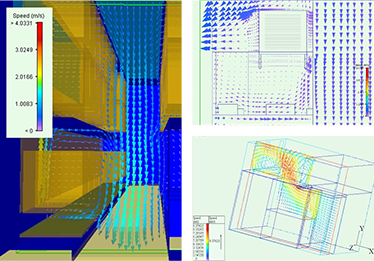

Airflow Simulation

The construction of cleanrooms not only requires precise control of temperature and humidity, but also relies heavily on the design and planning of airflow patterns. Since airflow is invisible and difficult to observe, its calculation is very complex. Therefore, during the planning phase, CFD (Computational Fluid Dynamics) software can be used for simulations to confirm whether the design meets the owner's requirements. This also significantly reduces the time and cost of trial and error during on-site troubleshooting.